Universal Drum Assembly for Cranes

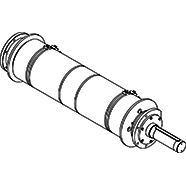

Applied in the lifting mechanisms on the cranes with heavy tonnage and long lifting height. Production lead time is 20 days. (excluding shipping time)

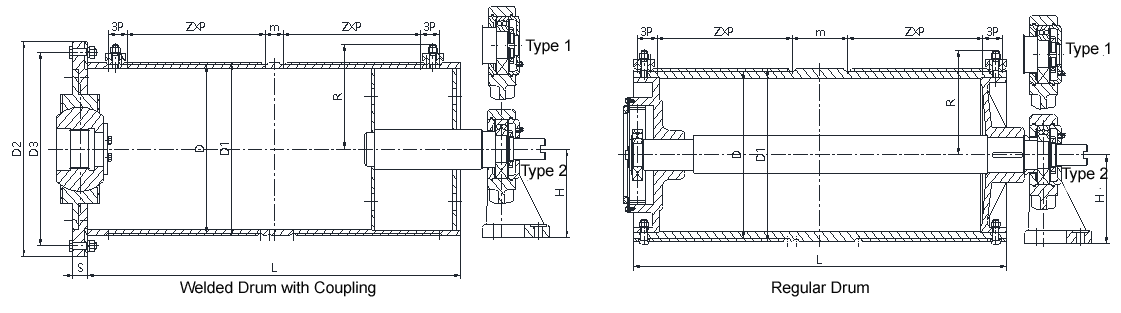

Nominal Dia.

300-500,200-300,500-800,800-1000

Drum Body Length

1500-2500,2500-3500,3500-4000

Categories:

Crane Drum

Parts Intro

Process Map

Overview

Overview

Just like crane wheels are easy to wear as the most vulnerable components in the traveling mechanism, drum assemblies from the hoisting mechanism are the same due to the long-term use of their grooves. Furthermore, when a drum becomes worn, it accelerates the wear of the wire rope, which can lead to significant safety hazards. On the other hand, replacing drums is a more intricate process compared to replacing crane wheels. It triggers the disassembly of the entire hoisting unit, including the hoisting motor, brake system, and wire rope, in conjunction with the hook (or any other attached hanger, which may complicate the procedure). To make a long story short, the quality of wire rope drums holds paramount importance in a crane.

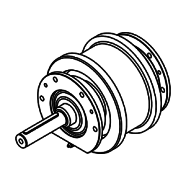

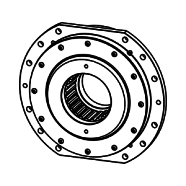

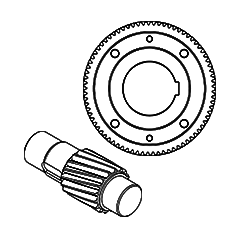

Purui specializes in manufacturing two types of drum assemblies: seamless pipe rope drums and Q355 or S355 steel plate drum shells. We utilize seamless steel tubes for smaller-diameter drums. Generally, rolling steel plates are used to manufacture crane drums with larger diameters. Cast iron drums feature a self-lubricating property, resulting in better compatibility with wire ropes. By changing the material of the drum shell, flange, stud, axis, and rope clamp, etc., it can adapt to low low-temperature working environment down to -40℃.

Custom-designed wire rope drums are commonly required with unique specifications to meet various projects. Our manufacturing capabilities enable us to meet specific needs in the market. The Purui steel plate rope drum can accommodate diameters of up to 3000mm, and the groove hardness and hardness depth can be customized as per actual application from 180 HB to 45 HRC. UT, MT, VT NDT reports on overall welding joints and weld seams will be provided for better safety assurance.

Drum assemblies that Purui manufactured feature compact structures, lightweight, and high-assembly precision. They are also frequently used parts of metallurgy, mining, port, and the energy industry.

Drum Assembly Display

Key words:

crane drum,lifting drum,drum assembly,hoisting drum,hoisting drum,crane parts factory,winch drum,cable drum,overhead crane drum

Online Inquiry

Contact us anytime by the Email or the WhatsApp button➡

We’ll respond promptly with a tailored solution.

Relevant Case

Applications in ZOOMLION Crawler Crane

Applications in SANY Truck Crane

New Design Drum Project for Port Construction

Hook Block Applications in the Metallurgical Overhead Crane Project

Contact Us

Tel: +86-18664956624

Email: ryanf@pr-drive.com

Add: No. 7 Duchang Road, Nanpu Street, Changyuan City, Xinxiang City, Henan Province, China

Copyright © Henan Purui Precision Machinery Co., Ltd.

This website already supports IPV6 Powered by 300.cn

SAF Coolest v1.3 设置面板 JHZSX-ZTTE-ZWSWE-ZXD

无数据提示

Sorry, there is no content in the current column!