Electric Hydraulic Grab Bucket for Crane

Whether you need the precision of an electric grab bucket, the power of an electric hydraulic system, or the structural optimization of the Paina series, Purui offers tailored grab solutions to meet the challenges of modern bulk material handling.

Parameters for Reference ⬇ Customizable as per Working Conditions ⬇

Petal No.: 2 / 3 / 4 / 5 / 6

Environment: Normal / Deck / Underwater / Waste / Bulk Material

Target Object: Coal / Sand / Scrap / Mining / Grain / Distiller's Grain

Capacity (m³): 2 / 3 / 4 / 5 / 6 / 8 | 10

Holding Weight/Volume (t/m³): 0.8~2.5

Categories:

Scroll Down for More

Electric & Hydraulic Grab Buckets: High-Efficiency Solutions for Bulk Material Handling

Grab buckets are essential tools in modern material handling systems, widely used in ports, steel mills, waste-to-energy plants, and bulk cargo terminals. Among them, electric grab buckets, electric hydraulic grab buckets, and specialized structural grab buckets like the Paina series represent advanced, energy-efficient solutions for various materials. This article introduces all three types, detailing their structure, advantages, and application fields.

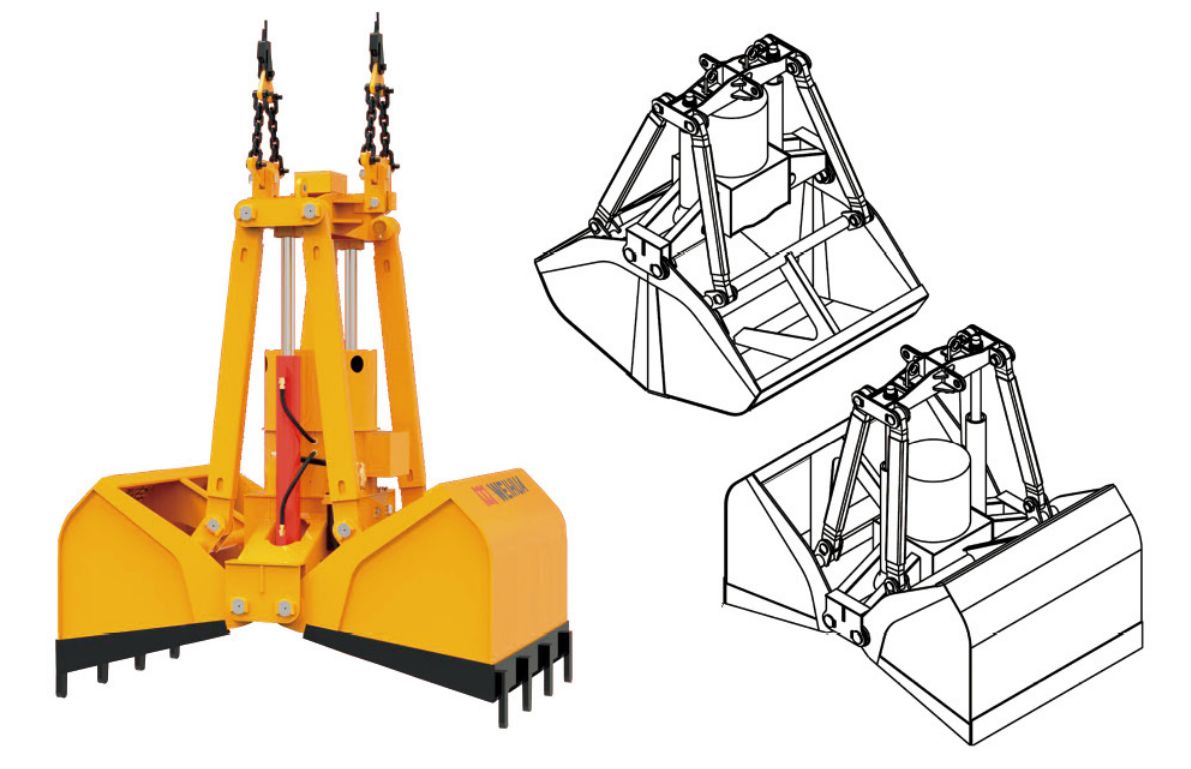

Electric Hydraulic Grab Bucket: Power Meets Versatility

The electric hydraulic grab bucket combines electrical, hydraulic, and mechanical systems into a compact, fully integrated unit. It is primarily used in applications such as:

-

Waste-to-energy incineration plants

-

Steel scrap handling and battery recycling

-

Municipal solid waste transfer stations

-

Bulk cargo terminals requiring fast cycle times

Available in multi-petal (orange peel type) and double-petal (clamshell type) configurations, these grabs are designed to handle irregular, high-density, and compressible materials. The hydraulic system operates the grab jaws independently of crane ropes, ensuring strong closing forces, deep penetration, and stable gripping even under difficult material conditions.

Technical advantages:

-

Load-sensing, constant power hydraulic system with pressure cutoff

-

High grab force and fast cycle time for maximum throughput

-

Hydraulic components sourced from top-tier imported brands

-

Optimized oil flow system for lower temperature rise and energy savings

-

Compact structure and aesthetic industrial design

-

Easy maintenance with modular hydraulic and electrical units

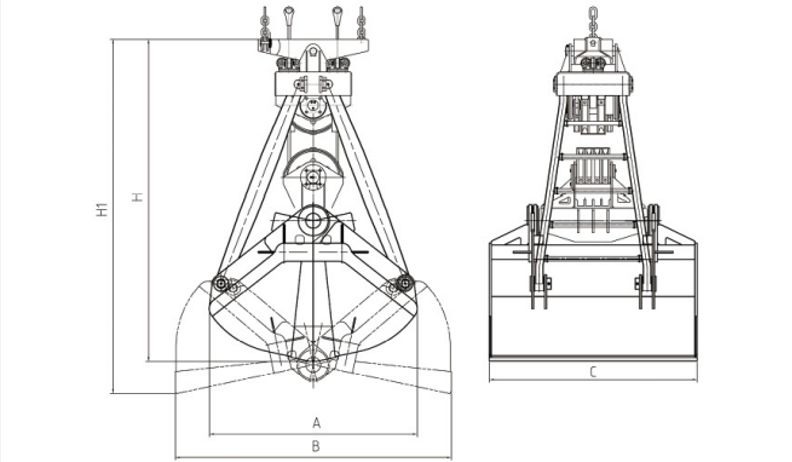

Paina Grab Bucket: Lightweight Structure with Heavy-Duty Performance

The Paina series grab bucket is specifically engineered for harbor gantry cranes and bridge-type ship unloaders, where efficient, continuous duty operation is required. Its structure is optimized for strength, balance, and weight efficiency.

Key structural and performance features:

-

Short lower bearing beam with high strength and reduced self-weight for enhanced dynamic performance

-

Fully closed-welded spreader structure provides independent force transmission, ensuring excellent lateral stability and bending resistance

-

Premium high-alloy steel bushings at hinge points extend the grab’s service life by 3–4 times compared to conventional models

-

Exceptional material-to-self-weight ratio of 1.5 to 1.9, signifying outstanding grabbing efficiency and payload capability

The Paina grab bucket is ideal for bulk materials such as coal, ore, grain, and fertilizer, where high turnover and equipment durability are essential.

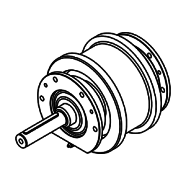

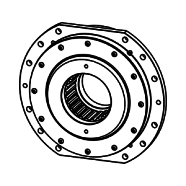

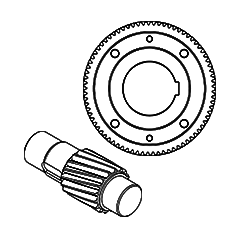

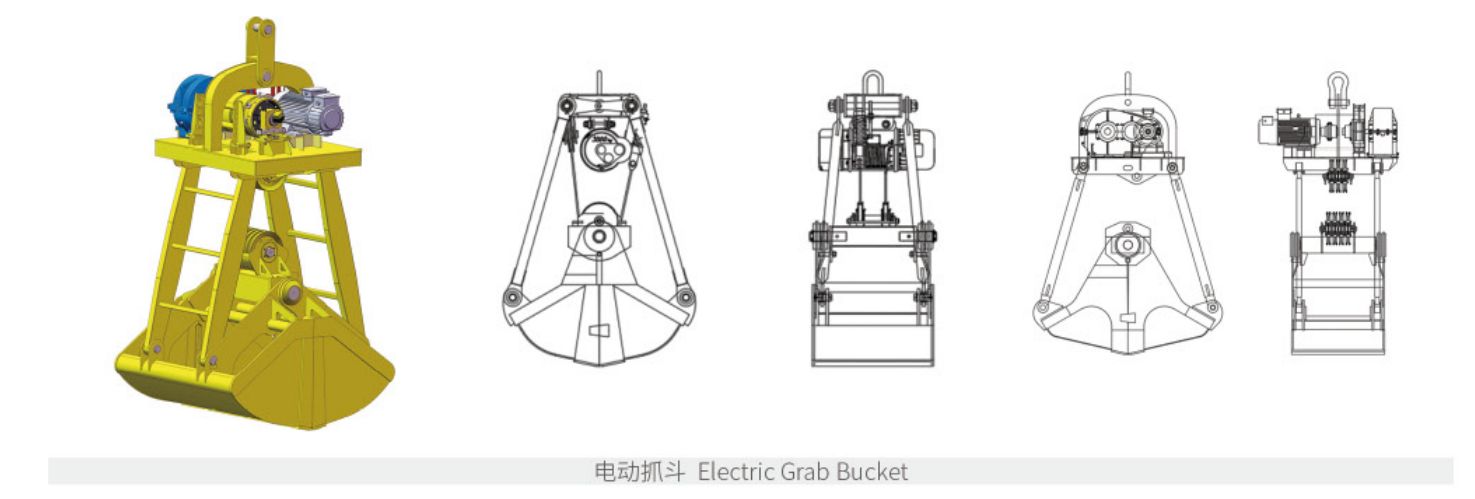

Electric Grab Bucket: Precision, Power, and Efficiency

The electric grab bucket is widely used with overhead cranes, gantry cranes, and multi-purpose hoisting systems. It features an integrated opening and closing mechanism, which allows for material handling at any height without relying on crane hoisting ropes for actuation. This makes the operation faster, more efficient, and easier to automate compared to traditional single-rope or four-rope grabs.

Key advantages of electric grab buckets include:

-

Higher productivity and easy installation

-

Independent motorized control system for precise open/close actions

-

High grabbing force fully utilized for material penetration and handling

-

No reliance on rope tension, unlike mechanical rope grabs

-

Suitable for lifting ores, coal, grain, or other granular materials

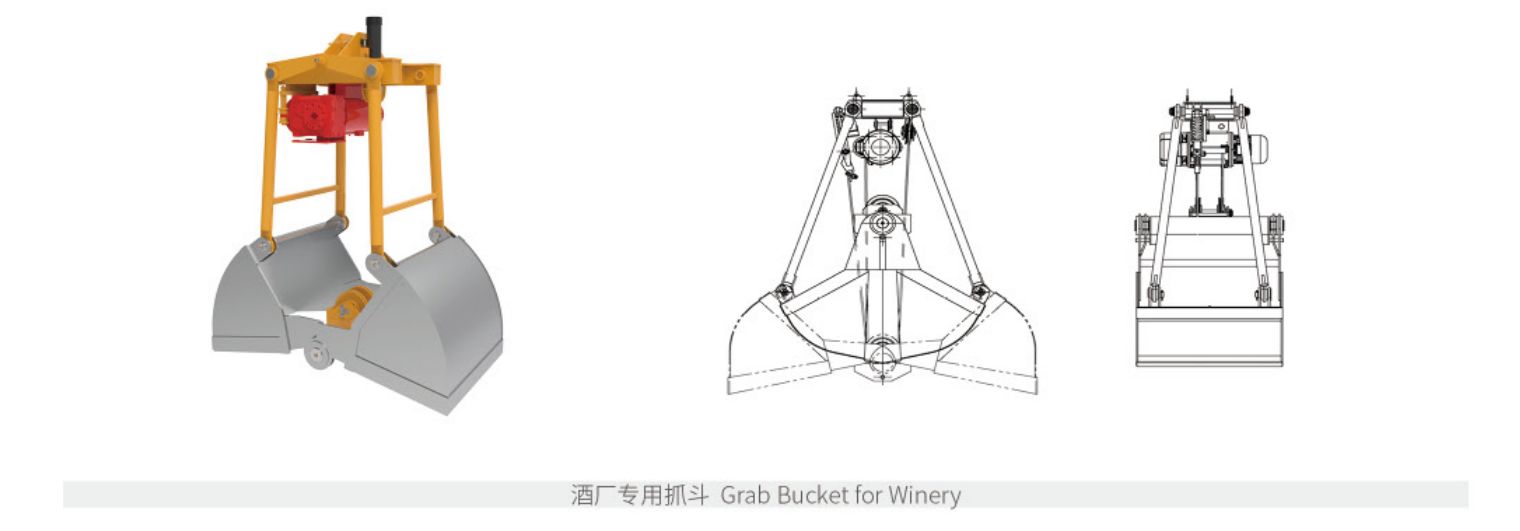

Some electric grabs are equipped with servo electric cylinders for ultra-precise actuation, especially in specialized environments like wineries. These models use a guide-column connection structure for high positional accuracy and ease of automation. To meet sanitary and durability requirements, food-grade 304 or 316L stainless steel is used for all wetted parts, offering corrosion resistance, heat tolerance, and a long service life.

Note: Electric grab buckets are not suitable for underwater operations, due to the sealed motor system and electrical components.

In the End

Whether you need the precision of an electric grab bucket, the power of an electric hydraulic system, or the structural optimization of the Paina series, Purui offers tailored grab solutions to meet the challenges of modern bulk material handling. Our engineered buckets are built to maximize productivity, minimize downtime, and withstand the harshest port and industrial environments.

For detailed specifications, 3D models, or engineering consultations, contact Purui today — your trusted partner in crane grapple technology.

Contact Emial: ryanf@pr-drive.com

Key words:

Online Inquiry

Contact us anytime by the Email or the WhatsApp button➡

We’ll respond promptly with a tailored solution.

Relevant Case

Applications in ZOOMLION Crawler Crane

Applications in SANY Truck Crane

New Design Drum Project for Port Construction

Hook Block Applications in the Metallurgical Overhead Crane Project

Contact Us

Tel: +86-18664956624

Email: ryanf@pr-drive.com

Add: No. 7 Duchang Road, Nanpu Street, Changyuan City, Xinxiang City, Henan Province, China

Copyright © Henan Purui Precision Machinery Co., Ltd.

This website already supports IPV6 Powered by 300.cn

SAF Coolest v1.3 设置面板 JHZSX-ZTTE-ZWSWE-ZXD

无数据提示

Sorry, there is no content in the current column!