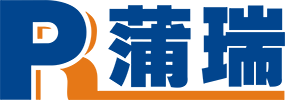

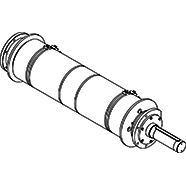

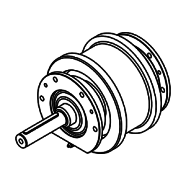

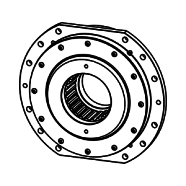

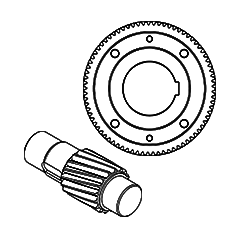

Universal Wheel Set

Applied in the driving mechanisms of overhead cranes. Production lead time is 20 days. (excluding shipping time)

Nominal Dia.

315,400,500,160,200,300,600,630,700,710,800,900,950

Drive/Idler

Drive Wheel,Idler Wheel

Thread Width

110,100,81,70

Manufacturing Process

Cast,Forge

Load Capacity Range:3~100t

Categories:

Wheel Sets

Parts Intro

Process Map

Overview

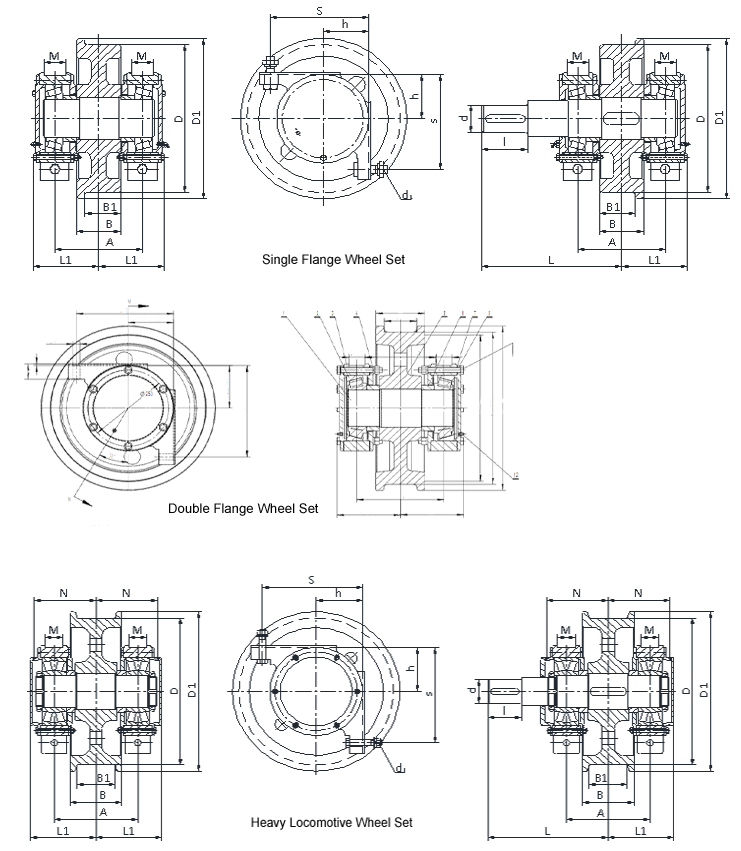

As integral components within the crane traveling mechanism, Crane Rail Wheels play a pivotal role in various lifting machines, including single-girder overhead cranes, double-girder overhead cranes, gantry cranes, port cranes, and other rail-mounted material handling equipment. These wheels come in a range of configurations, encompassing single-flange wheels, double-flange wheels, and other specialized nonstandard designs. The materials used in the construction of these wheels include 2CrMo4, ZG340-640, ZG50SiMn, 65Mn, 42Cr, etc., and more. At Purui, we employ diverse techniques tailored to the specific materials, expertly controlling the quenching and tempering temperatures to achieve the desired metallographic structure and optimal mechanical properties.

We employ three distinct heat treatment methods customized to specific requirements: Firstly, hardening and tempering yield a wheel surface hardness of HB300-380, primarily suitable for standard crane products. Secondly, surface medium frequency quenching and tempering result in a wheel surface hardness of HB300-380 or HRC50-56, ideal for products requiring low wheel center hardness and high wheel surface hardness, and when complete heat treatment is not feasible. Lastly, hardening and tempering lead to a wheel surface hardness of up to HRC50-56. Wheel surface hardness diminishes with depth due to material variations, with forged alloy steel wheels featuring a hardening layer depth of up to 15mm, ensuring minimal hardness attenuation. This method finds extensive use in applications such as port cranes and bucket-wheel excavators.

To minimize the risk of flange wear, breakage, and mechanical overload, while maximizing the longevity of the wheels, crucial factors like design, wheel material, wheel diameter, wheel flange design, wheel tread profile, wheel hardness, bearing type, and heat treatment must be evaluated before finalizing the combination.

Assembly Display

Key words:

wheel set,crane wheel,idle wheel,driving wheel,wheel manufacturer,crane factory,crane trolley wheels,overhead trolley wheels

Online Inquiry

Contact us anytime by the Email or the WhatsApp button➡

We’ll respond promptly with a tailored solution.

Relevant Case

Applications in ZOOMLION Crawler Crane

Applications in SANY Truck Crane

New Design Drum Project for Port Construction

Hook Block Applications in the Metallurgical Overhead Crane Project

Contact Us

Tel: +86-18664956624

Email: ryanf@pr-drive.com

Add: No. 7 Duchang Road, Nanpu Street, Changyuan City, Xinxiang City, Henan Province, China

Copyright © Henan Purui Precision Machinery Co., Ltd.

This website already supports IPV6 Powered by 300.cn

SAF Coolest v1.3 设置面板 JHZSX-ZTTE-ZWSWE-ZXD

无数据提示

Sorry, there is no content in the current column!